Lokacin da masana'antu a faɗin duniya suka yi odarinjin rufe tire, amai rufe tiren MAP, ko kumainjin marufi na fata mai injin injindaga DJPACK (Wenzhou Dajiang Vacuum Packaging Machinery Co., Ltd.), tambaya ɗaya da ake yawan yi ita ce:

"Me yasa nake buƙatar aika tire na da fim ɗin zuwa masana'antar ku?"

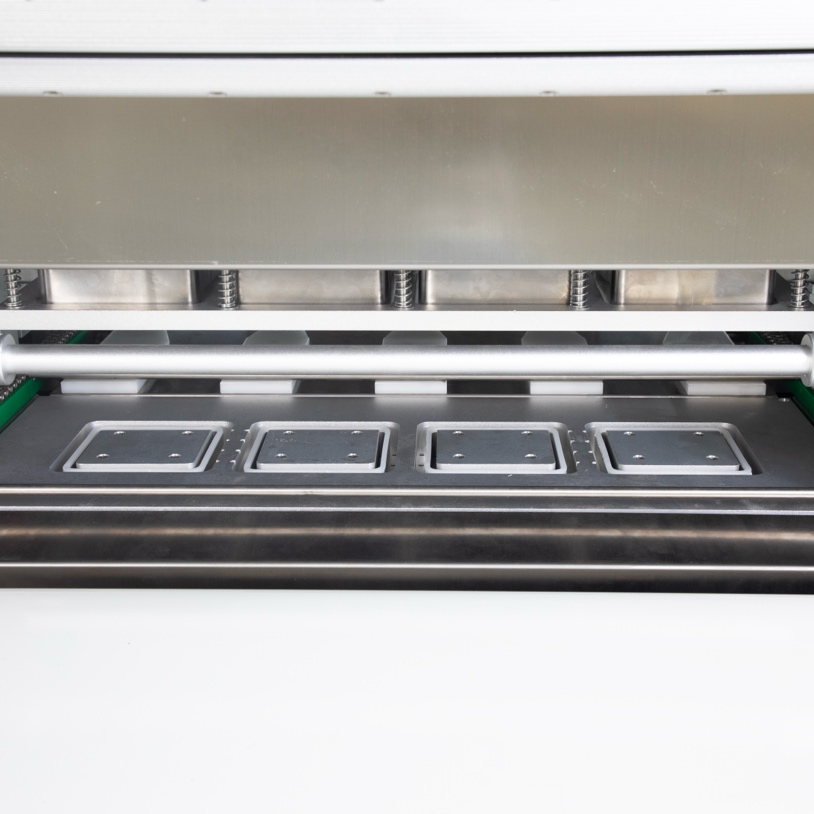

Da farko, yana iya zama kamar wani mataki. Amma ga kayan marufi, wannan matakin yana da mahimmanci. A gaskiya ma, ita ce hanya mafi aminci don tabbatar da cewa sabuwar na'ura tana aiki ba tare da wata matsala ba da zarar ta isa wurin abokin ciniki.

Wannan labarin ya bayyana—ta amfani da harshe mai sauƙi da kuma ainihin dabarun injiniya—dalilin da yasa tire da fina-finai suke da mahimmanci, yadda suke tasiri ga daidaiton mold, da kuma dalilin da yasa masana'antun duniya ke cin gajiyar wannan tsari.

1. Kowace Tire Tana Da Sauƙi Har Sai Ka Yi Ƙoƙarin Rufe Ta

Ga masu siye da yawa, tiren filastik tiren filastik ne kawai.

Amma ga wani mai ƙerainjunan rufe tire, kowane tire abu ne na musamman wanda ke da nasa yanayin halittar, yanayin kayansa, da kuma buƙatun rufewa.

1.1. Matsalar Girma: Kowa yana aunawa daban-daban

Abokan ciniki daga ƙasashe daban-daban suna auna tsayi ta hanyoyi daban-daban:

- Wasu ma'aunigirma na ciki(sararin da za a iya amfani da shi a cikin akwatin).

- Wasu suna aunagefen waje(wanda ke shafar ƙirar mold kai tsaye).

- Wasu suna auna sawun ƙasa kawai, ba buɗewar sama ba.

- Wasu kuma ba sa kula da tsayin flange ɗin.

Wannan yana haifar da rashin fahimta saboda ƙirar da aka keɓance tana buƙatarainihin bayanan rim-to-rim, ba kimanin lambobi ba. Ko da karkacewar 1-2mm na iya shafar aikin hatimi.

Lokacin da DJPACK ya karɓi tiren zahiri:

- Injiniyoyi na iya ɗaukar ma'auni daidai

- An tsara mold ɗin ne da tsarin gefen da ya dace

- Babu haɗarin "tire bai dace da mold ba" ko kuma "fim ɗin ba zai rufe" matsalolin ba

2. A faɗin duniya, Tireloli suna zuwa cikin siffofi marasa iyaka

Ko da tire biyu suna da girma ɗaya ko girman da aka yi amfani da shi, tsarinsu na iya bambanta gaba ɗaya. Wannan shine ɓangaren da yawancin masu siye ba sa fahimta har sai sun sayi injin rufewa.

2.1. Faɗin Tire Ya Bambanta da Yanki

Wasu ƙasashe suna samar da tire masu kunkuntar gefuna masu rufewa; wasu kuma suna fifita gefuna masu faɗi don ƙarfi.

Dole ne mold ya dace da waɗannan gefuna daidai - in ba haka ba sandar rufewa ba za ta iya samar da matsin lamba mai daidaito ba.

2.2. Tire na iya zama a tsaye, a kusurwa, ko kuma a lanƙwasa

Bangon tire na iya zama:

- a tsaye daidai

- ɗan taurare kaɗan

- mai kusurwa mai zurfi

- mai lanƙwasa a hankali

Waɗannan ƙananan bambance-bambancen suna tasiri ga yadda tiren yake a cikin mold da kuma yadda matsin lamba na rufewa ke bazuwa a saman sa.

2.3. Kusurwar Flange Ba Koyaushe A Daidaita Take Ba

A cikin tire da yawa, flange ɗin ba shi da faɗi—yana ɗan lanƙwasa, lanƙwasa, ko ƙarfafawa don a tara shi. Wannan kusurwar tana shafar daidaiton rufewa kai tsaye. Idan mold ɗin bai yi daidai da kusurwar ba, ɗigon iska na iya bayyana ko da lokacin da zafin jiki da matsin lamba suka yi daidai.

2.4. Samfurin Tire yana Ba da damar Daidaita Mold ɗin da Ya Kamata

Injiniyoyin DJPACK suna kimantawa:

- lanƙwasa gefen

- kauri

- yanayin flange a ƙarƙashin matsin lamba

- kwanciyar hankali a bango

- sassaucin tire a ƙarƙashin zafi

Wannan yana ba su damar tsara ƙira waɗanda ba wai kawai suke daidai ba har ma dabarga a ƙarƙashin maimaita sake zagayowar hatimi, yana ba abokan ciniki sakamako mai ɗorewa da tsawon rai na injin.

3. Dalilin da yasa DJPACK ke buƙatar aƙalla tire 50 don gwaji

Abokan ciniki da yawa suna tambaya:"Me yasa kuke buƙatar tire da yawa haka? Shin kaɗan ba su isa ba?"

A gaskiya, a'a.

3.1. Ba za a iya sake amfani da wasu Tire ba bayan gwaji

Idan an rufe tire da zafi kuma an cire fim ɗin don dubawa:

- Tire mai rufi da PE zai iya yagewa

- Flange na iya canzawa

- Matakan manne na iya shimfiɗawa

- Tiren na iya ɗan lanƙwasa kaɗan a ƙarƙashin zafi

Da zarar wannan ya faru, ba za a iya amfani da tiren don wani gwaji ba.

3.2. Ana Bukatar Gwaje-gwaje Da Dama Don Daidaitawa

Don inganta saitunan masana'anta, injiniyoyi dole ne su gudanar da gwaje-gwaje da dama don tantancewa:

- mafi kyawun zafin rufewa

- lokacin rufewa mai kyau

- ƙimar matsin lamba daidai

- daidaiton daidaitawa

- santsi na buɗewa/rufewa na mold

- yanayin tashin hankali na fim

Kowace gwaji tana cin tire.

3.3. Nakasa Yana Faruwa Bayan Yawan Fuskantar Zafi Mai Yawan Tasiri

Idan aka kawo tire kaɗan kawai, ana gwada tiren iri ɗaya akai-akai. Zafi, matsin lamba, da motsi na inji na iya canza su a hankali. Tiren da ya lalace zai iya ɓatar da injiniyan ya yi tunani:

- mold ɗin ba daidai ba ne

- injin yana da matsalolin daidaitawa

- sandar rufewa tana da matsin lamba mara daidaituwa

Kawaitiren sabo da marasa tsariba da damar yin hukunci mai kyau.

3.4. Isassun Samfura Suna Kare Mai Saye da Mai Masana'anta

Isassun tire suna tabbatar da:

- Babu haɗarin girman mold ɗin da bai dace ba

- Sakamakon gwajin masana'anta mai inganci

- Yarda da injin santsi

- Ƙananan matsaloli yayin shigarwa

- Tabbatar da aikin rufewa lokacin isowa

Yana amfanar duka biyun sosaimutummai gyara da abokin ciniki.

4. Me Yasa Kayan Tire Ya Fi Muhimmanci Fiye da Yadda Masu Sayayya Ke Tsoma

Ana yin tiren da ake amfani da su wajen rufe marufi daga nau'ikan kayayyaki daban-daban:

- PP (Polypropylene)

- DABBOBI / ABINCIN ƊAN KWALI

- CPET

- PP-PE mai layuka da yawa

- Roba masu lalata muhalli

- Tire na aluminum

- Tirelolin takarda masu rufi da PE

Kowace abu tana da halaye daban-daban a ƙarƙashin zafi.

4.1. Yanayin Zafin Narkewa Daban-daban

Misali:

- Tirelolin PP suna buƙatar yanayin zafi mai yawa na rufewa

- Tiren dabbobin gida suna laushi da sauri kuma suna buƙatar ƙarancin zafi

- Tirelolin CPET suna jure zafi mai yawa don amfani da tanda

- Rufin PE yana da takamaiman wuraren kunna narkewa

4.2. Wayar da kan Zafi ke Shafar Lokacin Rufewa

Wasu kayan suna shan zafi a hankali.

Wasu suna shan zafi da sauri.

Wasu suna laushi ba tare da daidaito ba.

DJPACK yana daidaita lokacin rufewa da matsin lamba bisa ga waɗannan halaye.

4.3. Nau'in Fim Dole ne Ya Dace da Kayan Tire

Rashin daidaito na iya haifar da:

- hatimin rauni

- gefuna masu narkewa

- fim ɗin da ke fashewa a ƙarƙashin zafi

- wrinkles masu rufewa

Wannan shine dalilin da ya sa aika tire-da fina-finan da suka dace-ke taimakawa wajen tabbatar da shawarwarin injiniya da suka dace.

5. Dalilin da yasa Fina-finai suke da mahimmanci kamar Trays

Ko da an yi amfani da tire mai kyau, rashin daidaiton fim ɗin na iya lalata hatimin.

5.1. Tsarin Fim Ya Bambanta Ta Hanyar Amfani

Fina-finai sun bambanta ta hanyar:

- kauri

- tsarin Layer

- Layer na kunna zafi

- ƙarfin rufewa

- rage girman hali

- SƘarfin treck

- Yawan watsa iskar oxygen

Man shafawa na tiren MAP da injin marufi na fata na injin tsabtace fata musamman suna buƙatar fina-finai masu dacewa daidai.

5.2. DJPACK Ba Ya Tilasta Wa Abokan Ciniki Su Aika Fim

Amma aika fim ɗin koyaushe yana haifar da:

- mafi kyawun saituna

- gwaji mafi daidaito

- amfani mai sauƙi a karon farko

Idan abokan ciniki ba za su iya aika fim ba, dole ne su ƙayyade kayan aikin. Wannan yana ba DJPACK damar amfani da fina-finai iri ɗaya yayin gwaji.

5.3. Dole ne a tabbatar da jituwa da Tire da Fim

Dole ne fim ɗin ya dace da kayan tire.

Dole ne a rufe fim ɗin da kyau ba tare da kumfa ko ɓuɓɓuga ba.

Dole ne a cire fim ɗin yadda ya kamata (idan yana da sauƙin cirewa).

Gwaji yana tabbatar da cewa an cika dukkan sharuɗɗa uku.

6. Me zai faru idan Abokan Ciniki ba su da tire ko fim tukuna?

DJPACK yana tallafawa sabbin masana'antu da kamfanoni masu tasowa waɗanda ba su da kayan marufi tukuna.

6.1. Ana iya siyan kayan amfani ta hanyar DJPACK

Kamfanin zai iya taimaka maka samun:

- Ma'aunin Tire Mai Canji

- Fim ɗin VSP

- Fim ɗin murfin MAP

- Ma'aunin Tire Mai Canji

Wannan yana rage matsin lamba ga masu farawa - muna taimaka muku nemo masu samar da kayayyaki masu inganci da aminci.

6.2. Ana jigilar kayan da ake amfani da su don gwaji tare da injin

Wannan yana tabbatar da cewa lokacin da abokin ciniki ya karɓi injin rufe tire, zai iya nan take:

- gwaji

- daidaita

- kwatanta

- masu aikin jirgin ƙasa

Rage lokacin isowa da kuma lokacin da za a iya amfani da shi don fara samarwa da sauri.

6.3. Shawarwari Kan Masu Kaya Na Dogon Lokaci Akwai

Don manyan buƙatun samarwa, DJPACK na iya ba da shawarar masu samar da kayayyaki masu ɗorewa, wanda ke sauƙaƙa wa abokan ciniki su sayi tire da fina-finai daga baya.

7. Tunani na Ƙarshe: Samfuran Yau Sun Tabbatar da Cikakken Hatimi Gobe

A duniyar marufi, daidaito shine komai. Tire mai kama da abu mai sauƙi a zahiri samfuri ne mai rikitarwa. Kuma idan aka haɗa shi da tsari da fim ɗin da ya dace, yana zama haɗuwa mai ƙarfi don sabo, aminci, da tsawon lokacin shiryawa.

Aika tire da fim ba matsala ba ce.

Shi ne tushen:

- ƙirar ƙira mai kyau

- aikin injin mai karko

- cikakken ingancin hatimi

- ƙananan matsaloli bayan shigarwa

- farawa cikin sauri

- tsawon rayuwar kayan aiki

Alƙawarin DJPACK abu ne mai sauƙi:

Kowace na'ura yakamata ta yi aiki daidai da lokacin da ta isa ga abokin ciniki.

Kuma hanya mafi kyau ta tabbatar da hakan ita ce fara da ainihin tire da fina-finan da abokin ciniki zai yi amfani da su.

Lokacin Saƙo: Disamba-15-2025

Waya: 0086-15355957068

Waya: 0086-15355957068 E-mail: sales02@dajiangmachine.com

E-mail: sales02@dajiangmachine.com